IMR

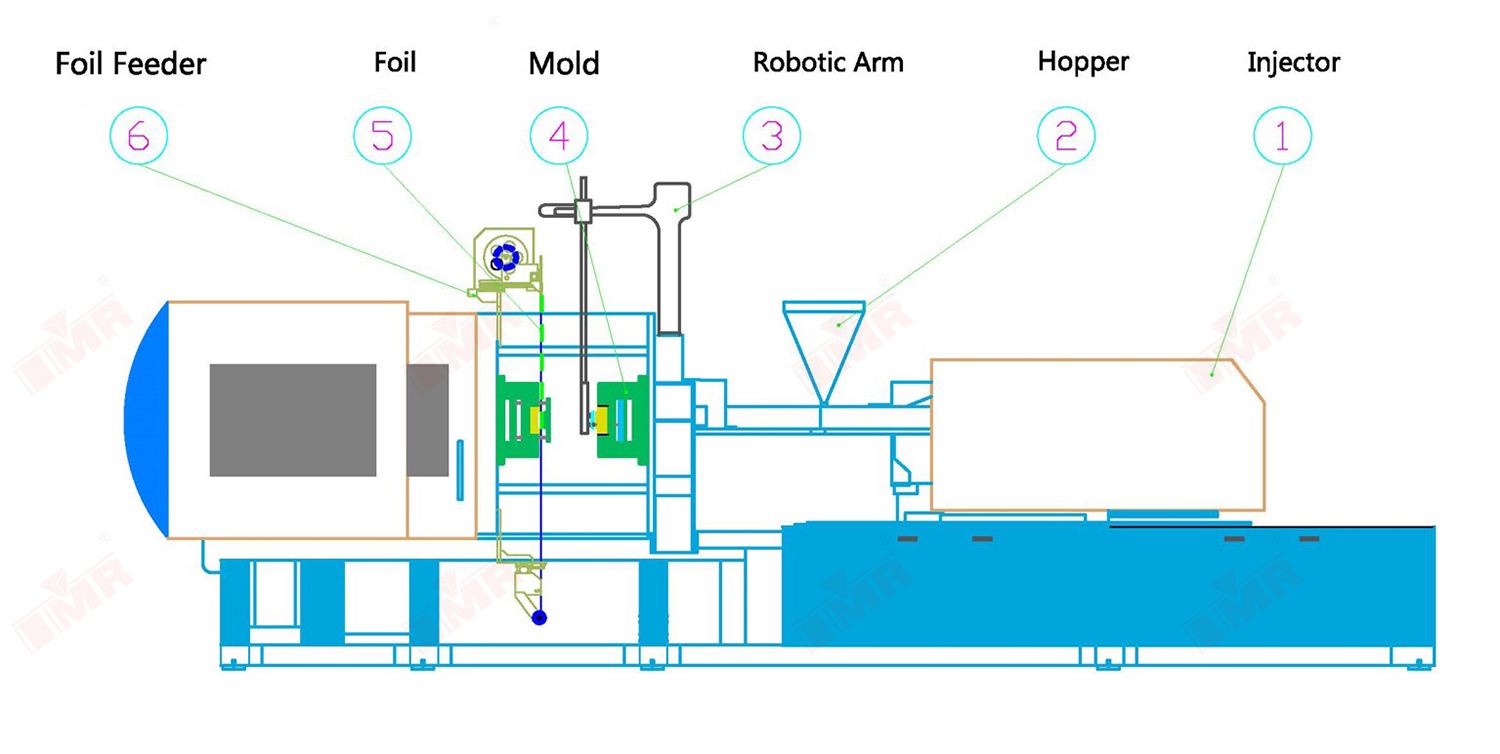

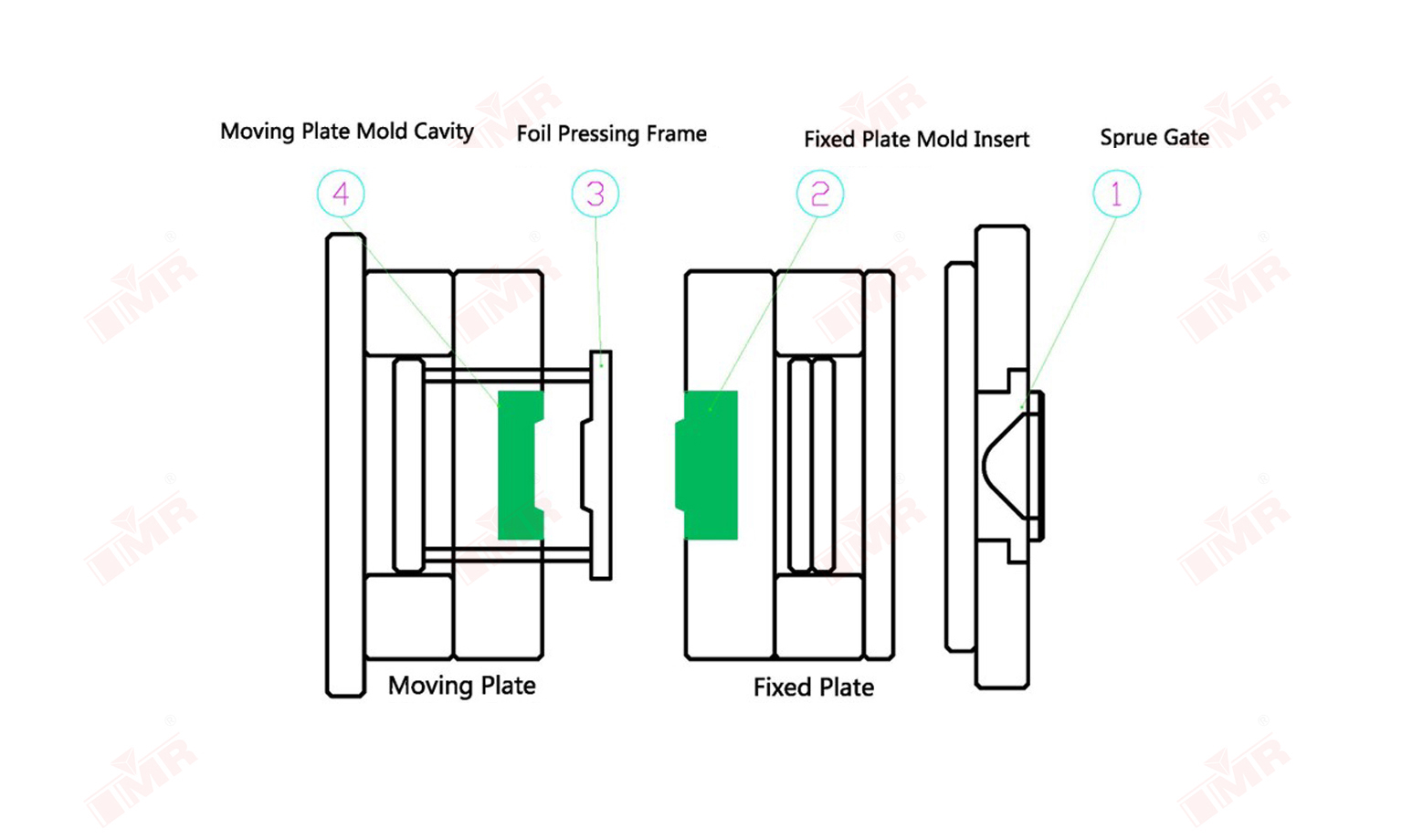

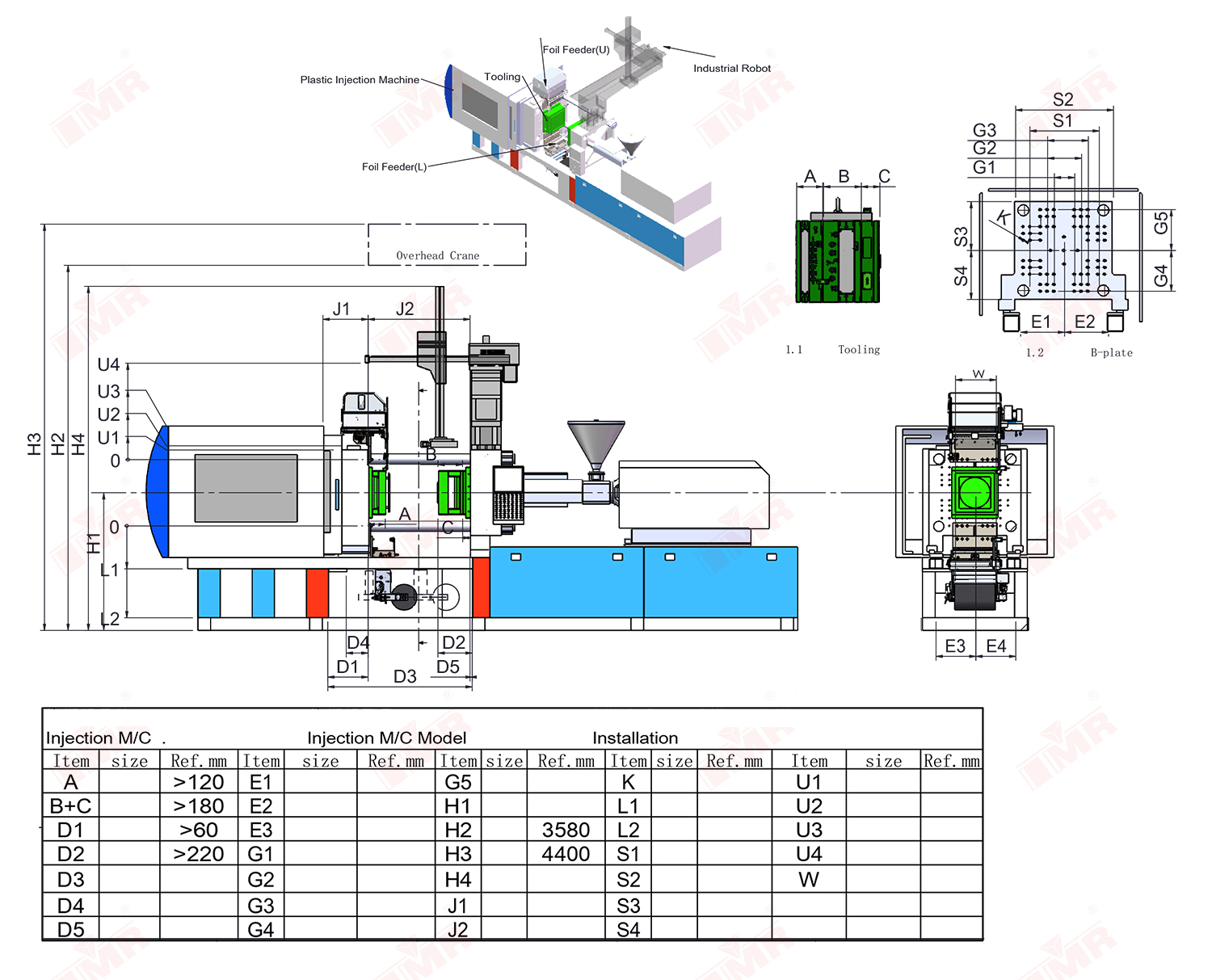

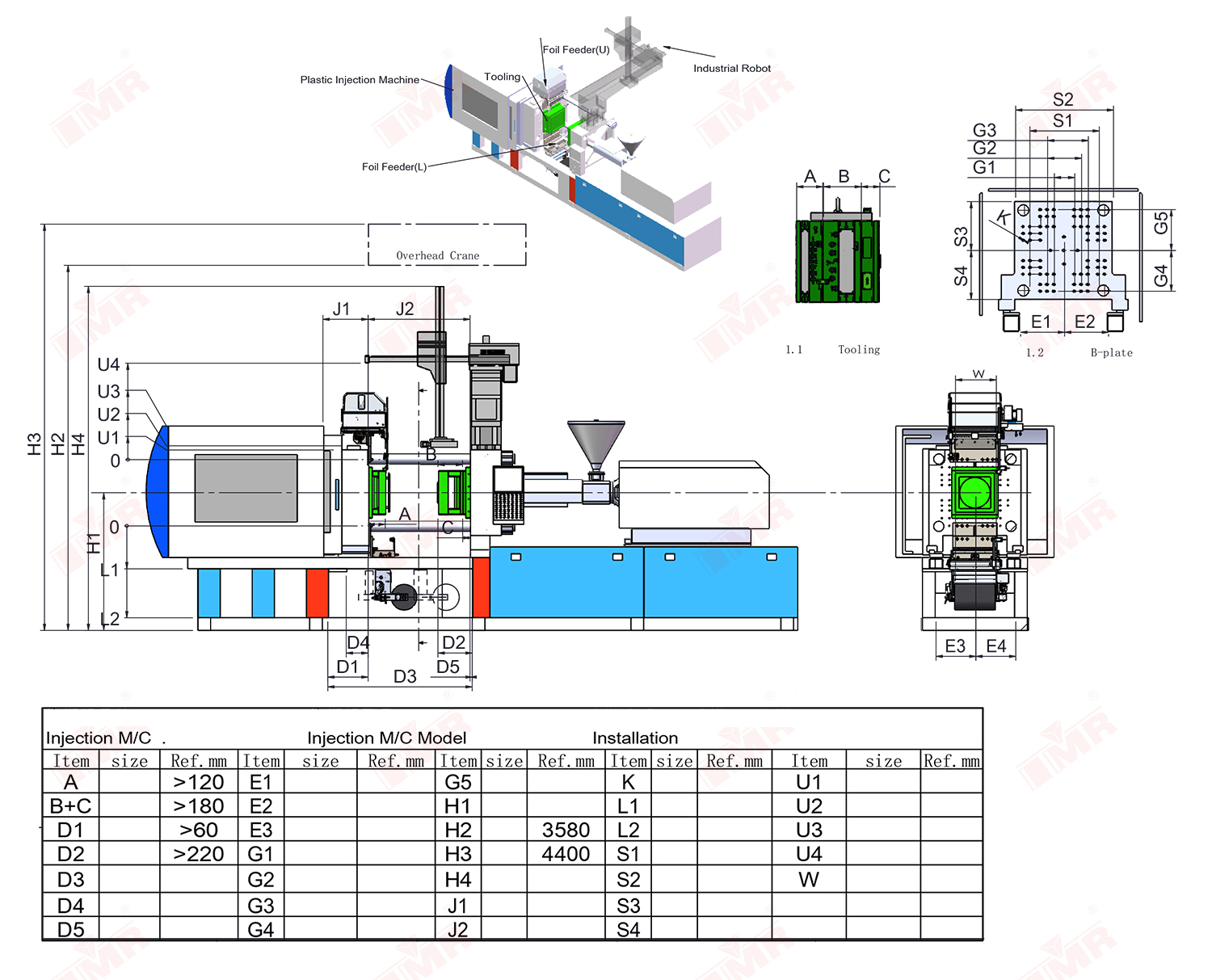

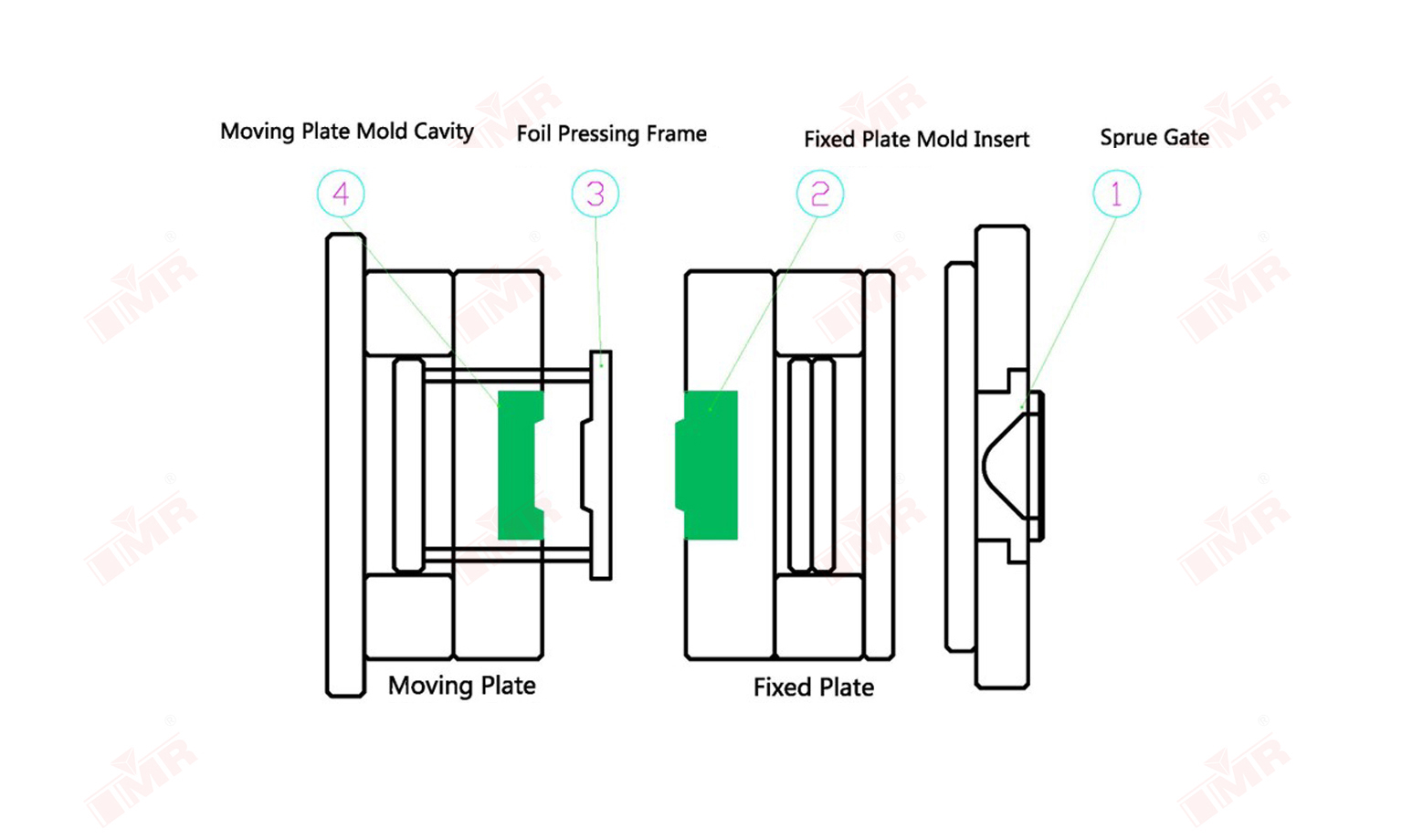

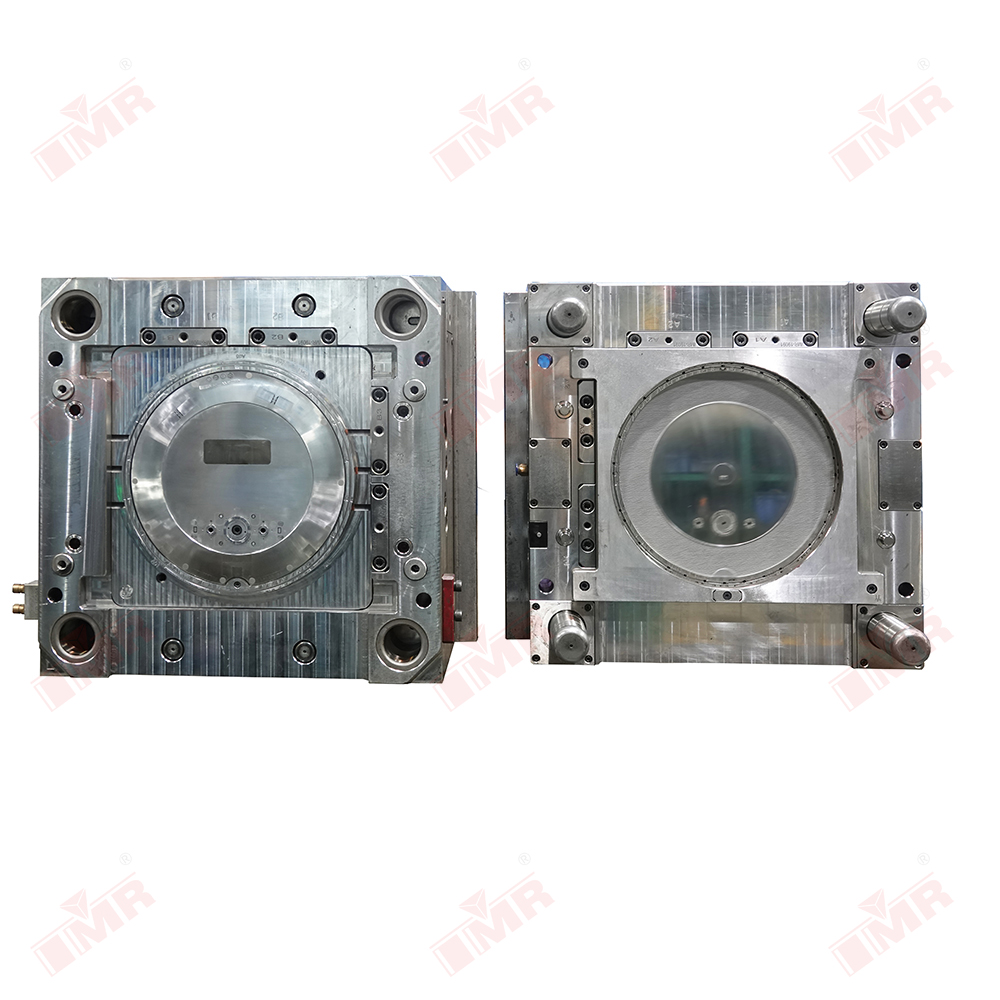

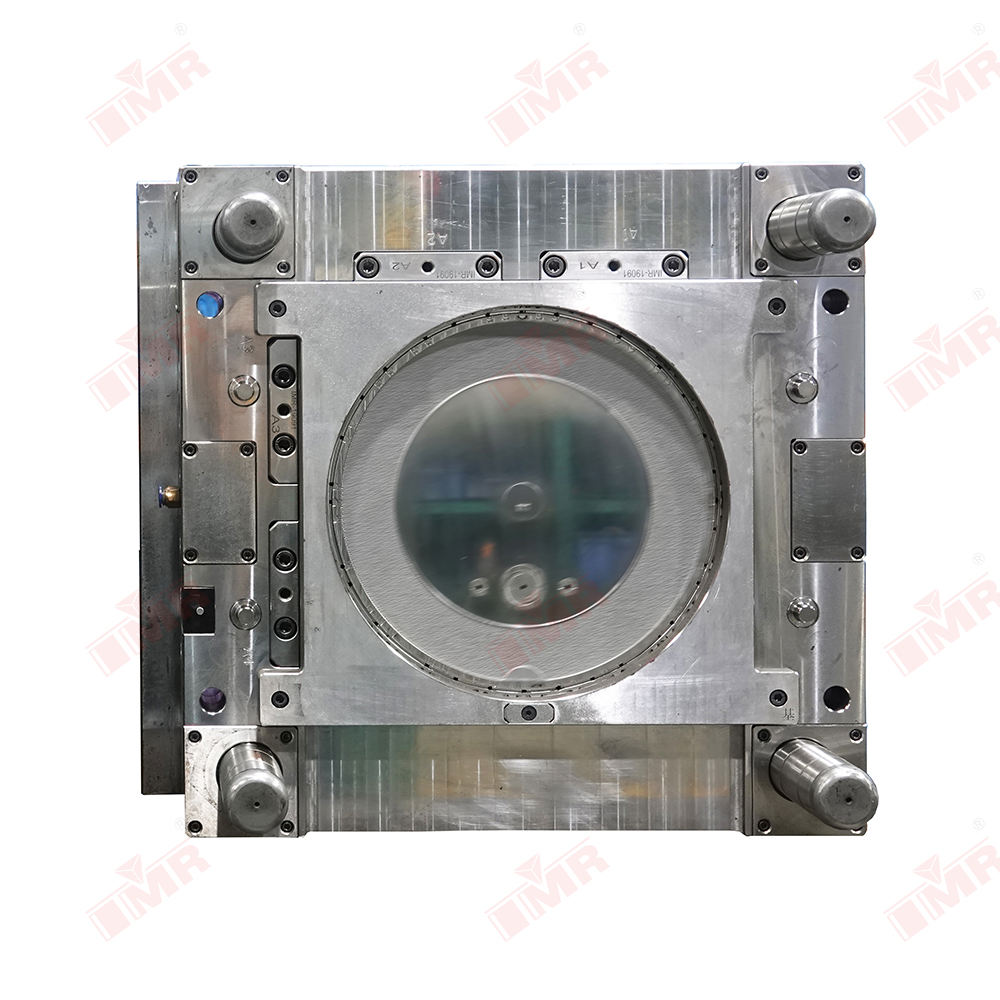

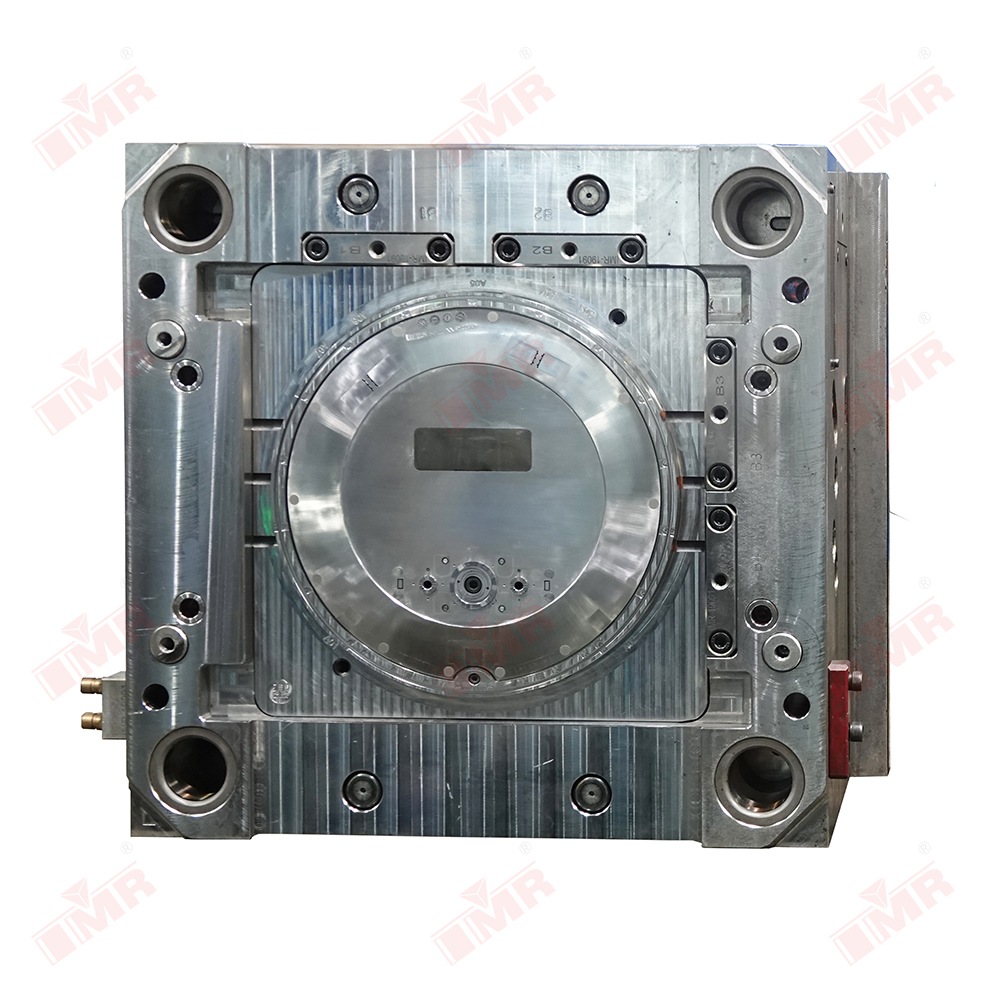

IMR (In-Mould Decoration by Roller) in-mold decoration technology prints decorative and functional patterns onto the film using a high-precision printer. The foil is then fed into a specialized molding mold through a high-precision foil feeding device. After precise positioning, the pattern on the foil is transferred to the surface of the plastic product under the high temperature and pressure of the plastic raw material.

-

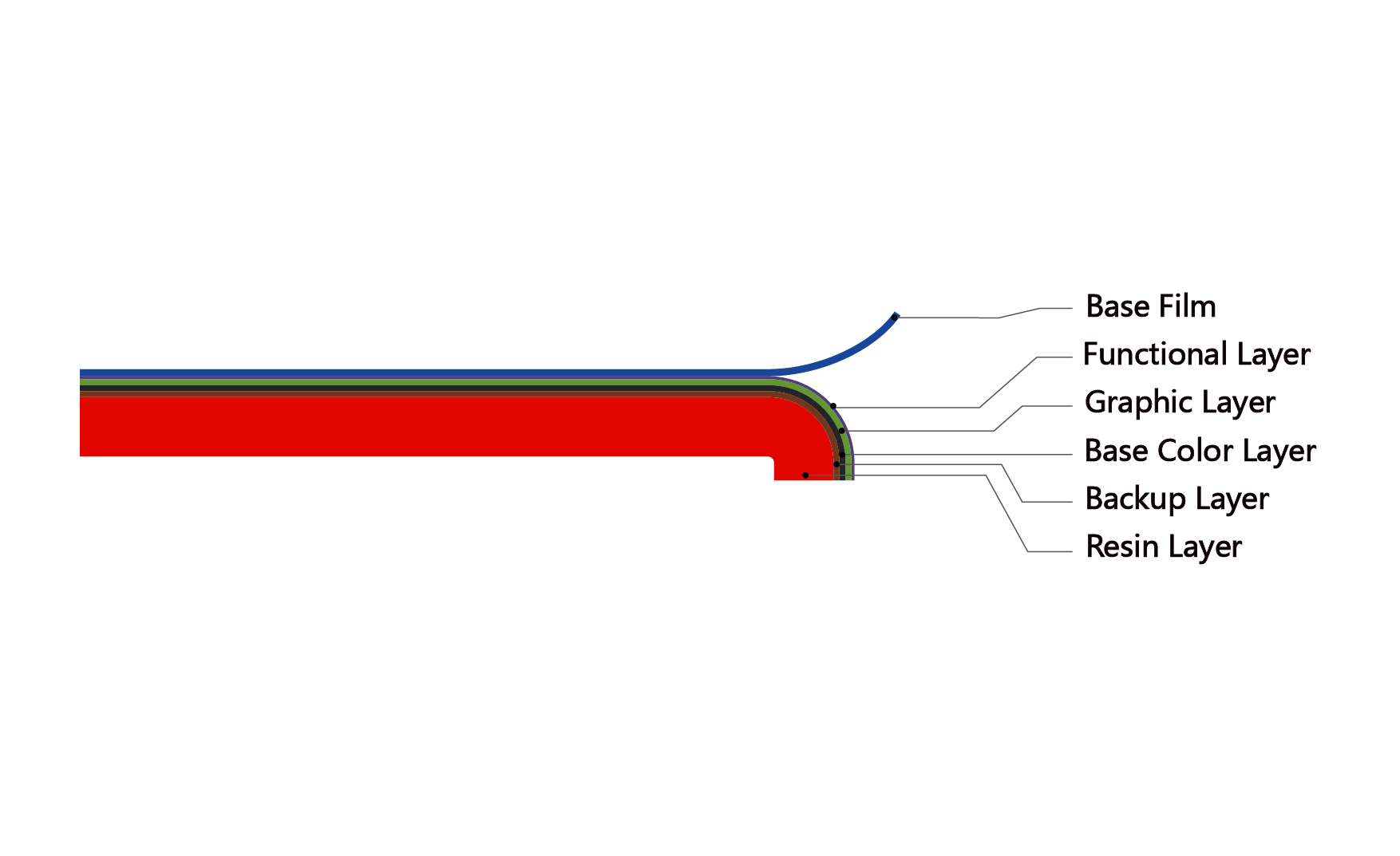

IML (In Mold Labeling), refers to a process where the film is printed, then formed by a forming machine, cut, and finally placed into the injection mold for production. The process is characterized by a hardened transparent film on the surface, a printed pattern layer in the middle, and a plastic layer on the back. Because the ink is sandwiched between layers, the product’s surface is protected from scratches and wear, maintaining vibrant colors that are resistant to fading over time.

-

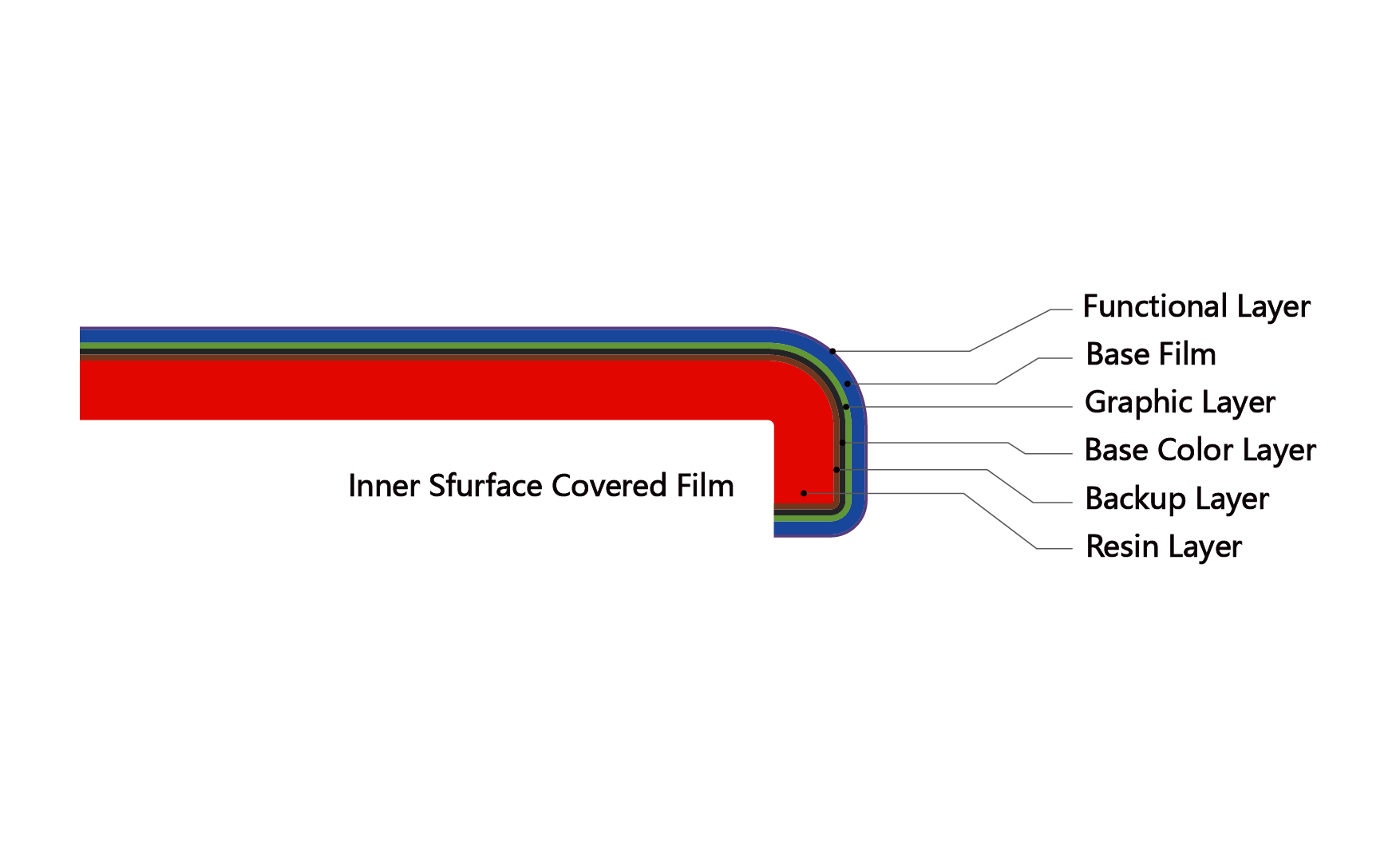

IMR (In-Mould Decoration by Roller) in-mold decoration technology prints decorative and functional patterns onto the film using a high-precision printer. The foil is then fed into a specialized molding mold through a high-precision foil feeding device. After precise positioning, the pattern on the foil is transferred to the surface of the plastic product under the high temperature and pressure of the plastic raw material. During the production process, the IMR foil substrate serves as the pattern carrier, leaving no substrate on the product's surface.

-

-

-

-

IMR process

Please feel free to consult us!