IML

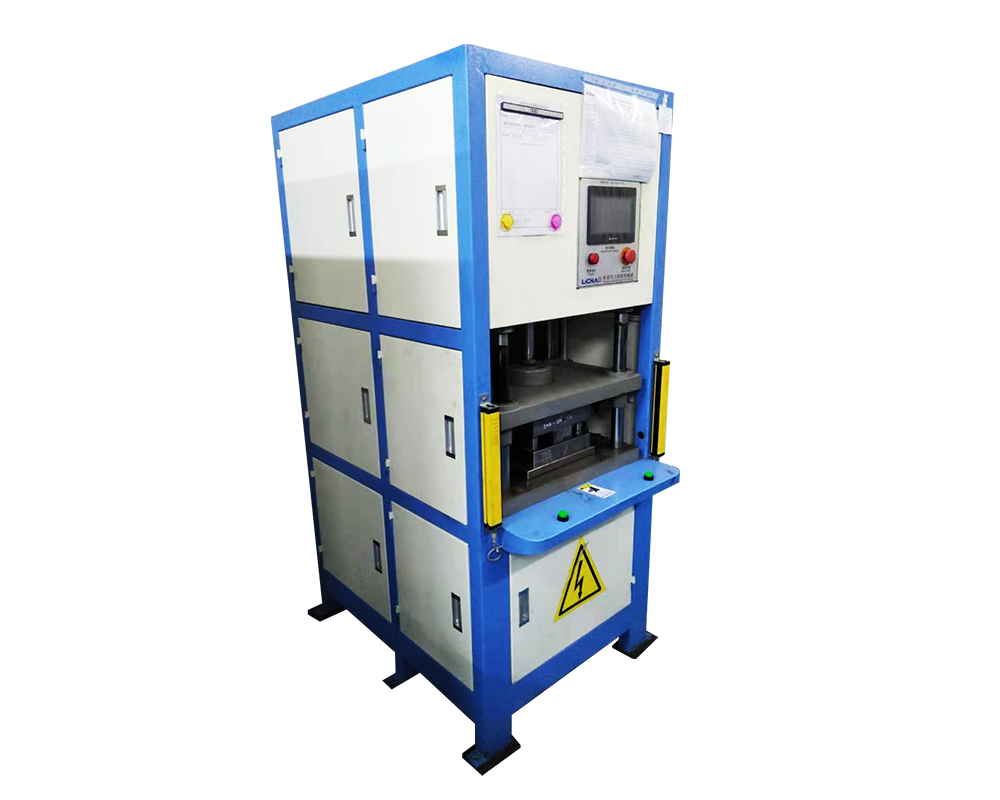

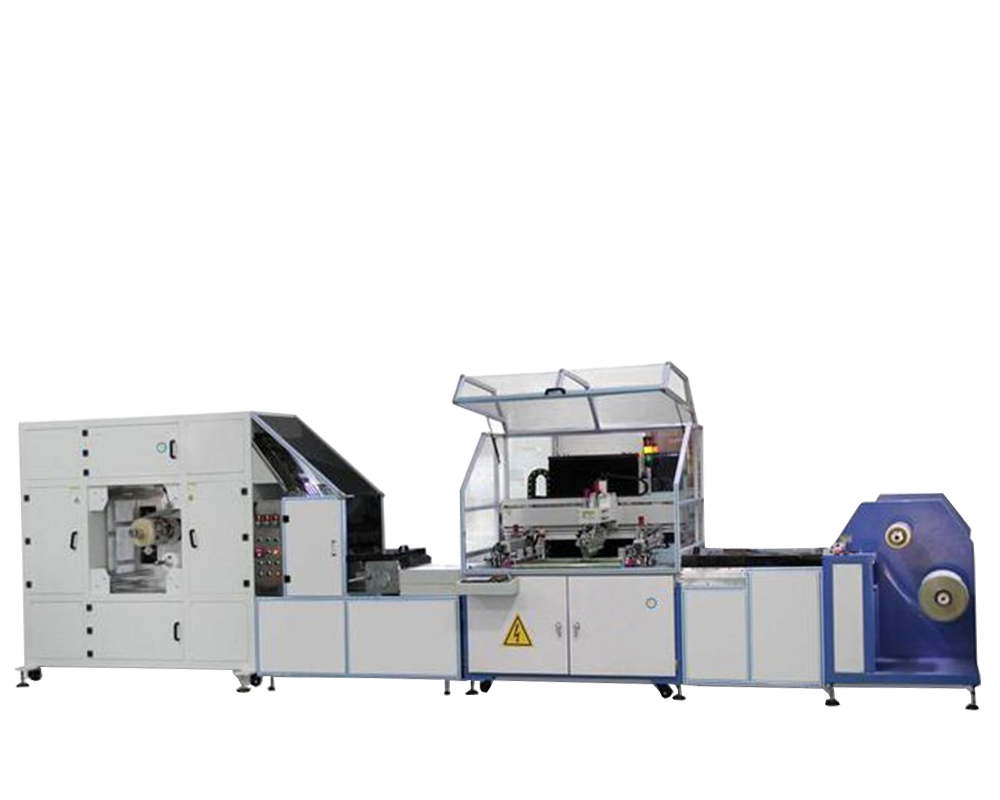

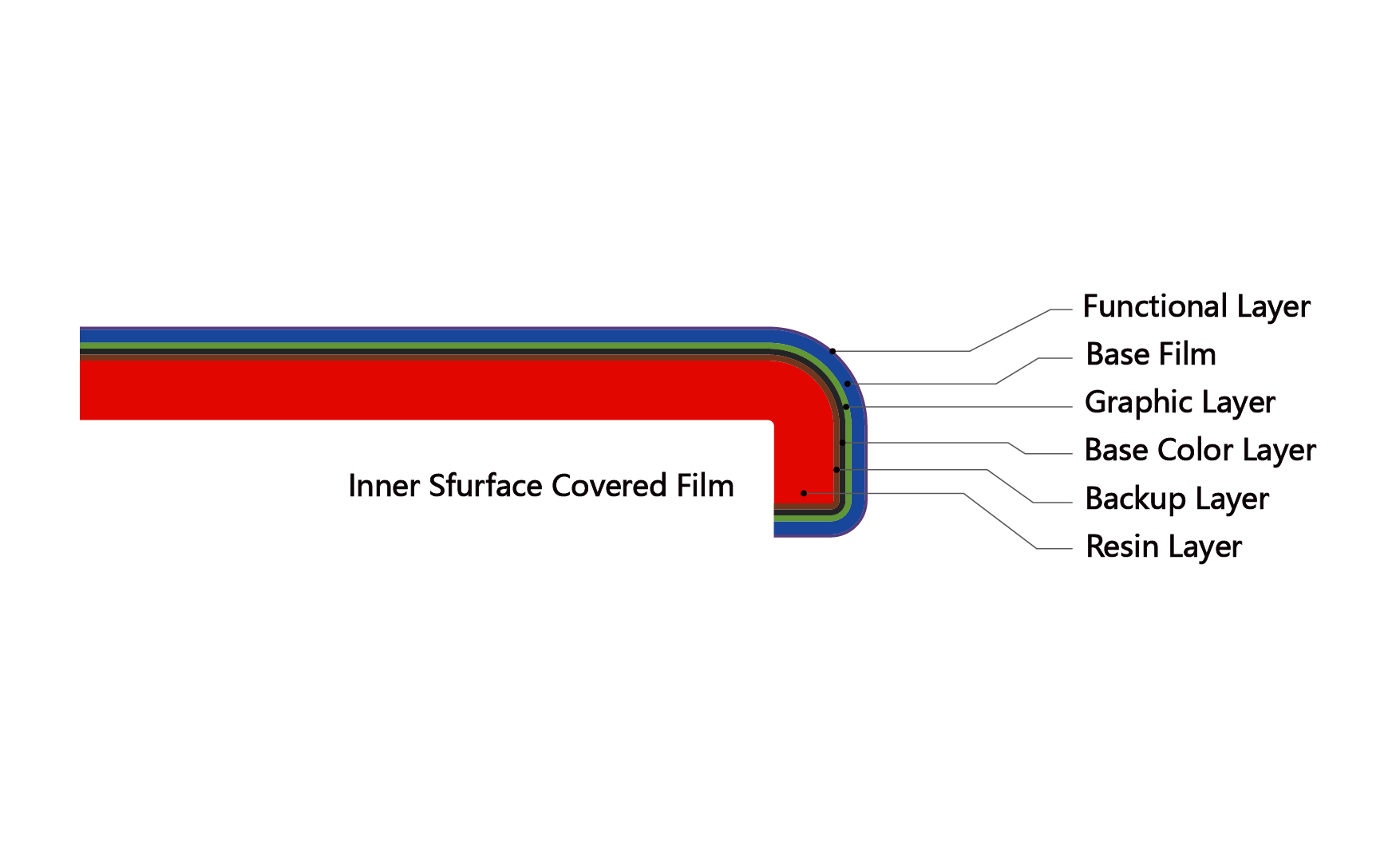

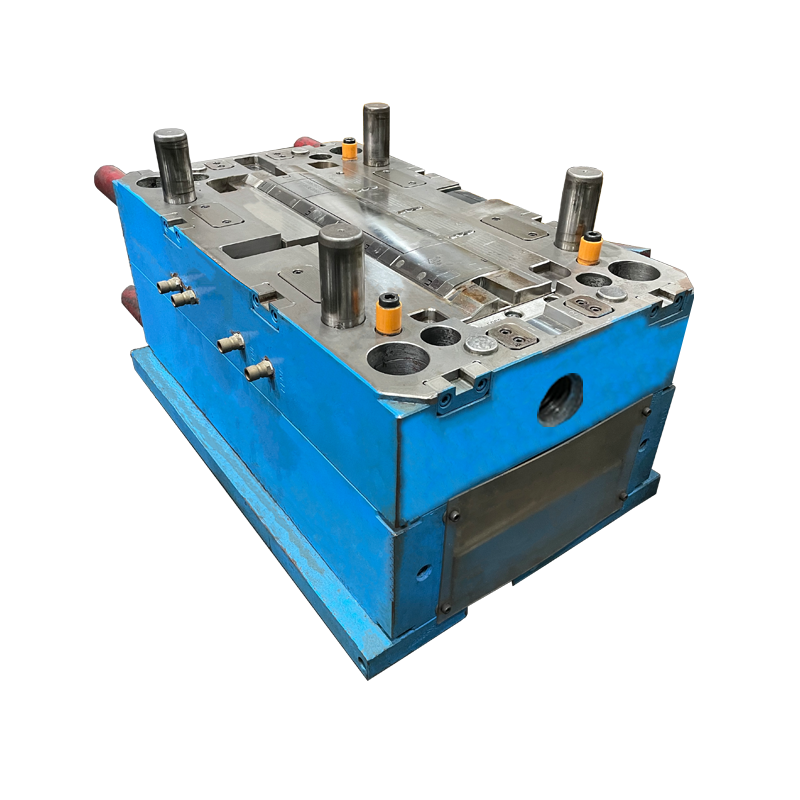

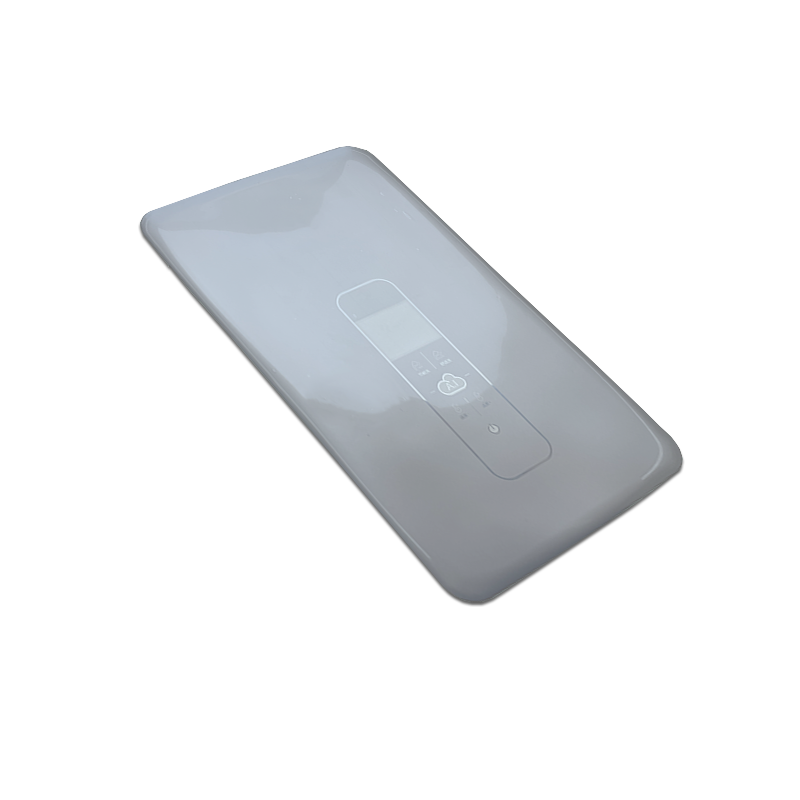

IML (In Mold Labeling), refers to a process where the film is printed, then formed by a forming machine, cut, and finally placed into the injection mold for production. The process is characterized by a hardened transparent film on the surface, a printed pattern layer in the middle, and a plastic layer on the back. Because the ink is sandwiched between layers, the product’s surface is protected from scratches and wear, maintaining vibrant colors that are resistant to fading over time.

-

IML (In Mold Labeling), refers to a process where the film is printed, then formed by a forming machine, cut, and finally placed into the injection mold for production. The process is characterized by a hardened transparent film on the surface, a printed pattern layer in the middle, and a plastic layer on the back. Because the ink is sandwiched between layers, the product’s surface is protected from scratches and wear, maintaining vibrant colors that are resistant to fading over time.

-

-

-

Technology Film thickness(mm) capacity Yield Cost stretching IMR 0.038~0.075 High

High

R&D

Middle

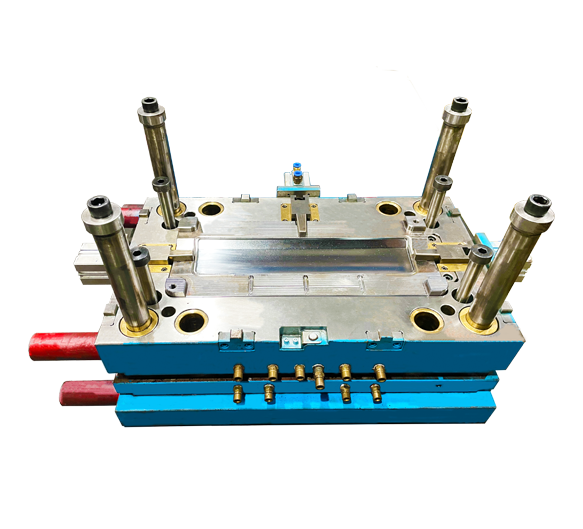

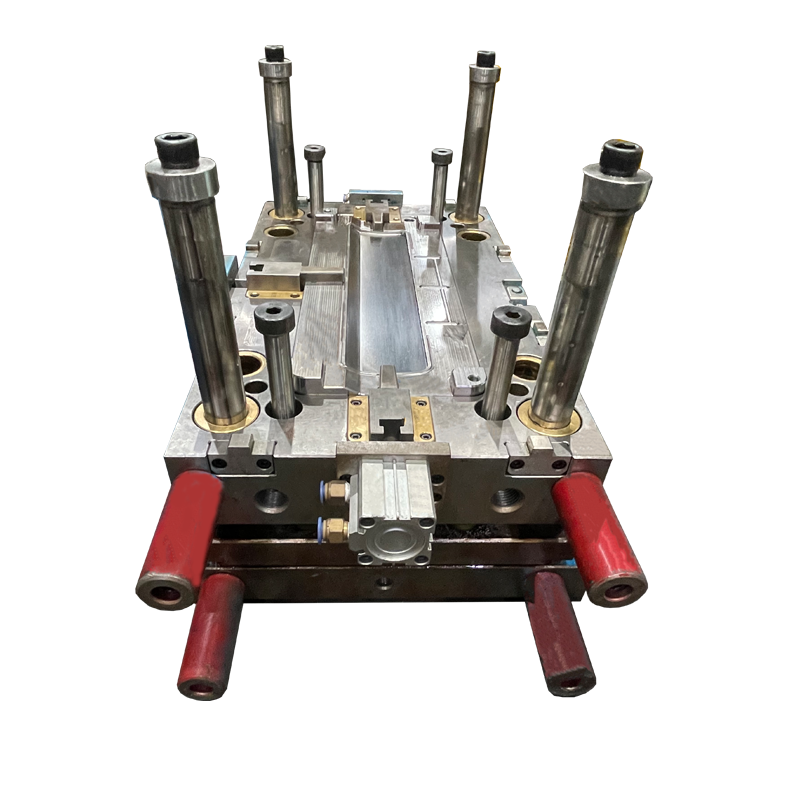

MOULD

Middle

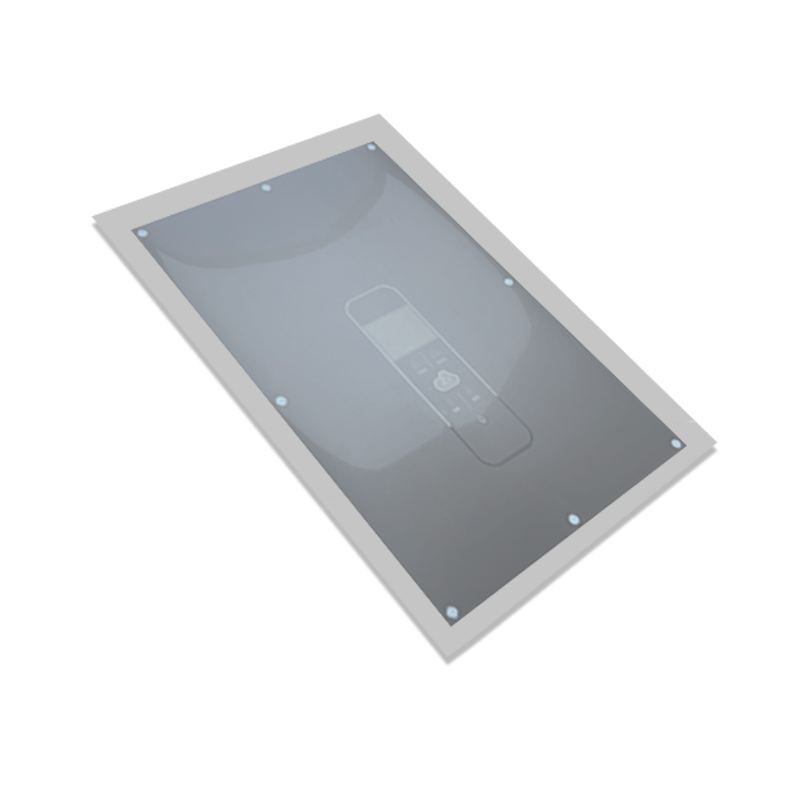

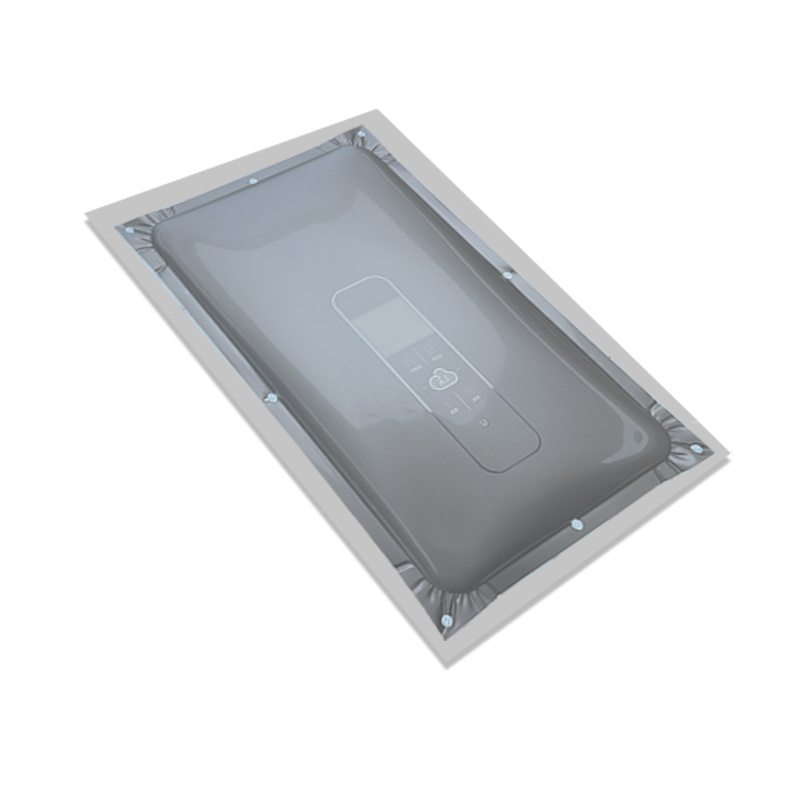

PRODUCT

Low

Low

IML 0.075~0.25 Middle

High

Low

High

Middle

Middle

IMT 0.075~0.25 Middle

Middle

High

High

High

Middle

IMR-TJ 0.075~0.3 High

Middle

Middle

High

High

High

INS/FIM 0.25~2.0 Middle

High

High

High

High

High

ATS 0.075~1.0 Middle

Middle

Low

Low

High

High

IME 0.125~1.0 Low

Low

High

High

High

Middle

IML process

Please feel free to consult us!